|

|

|

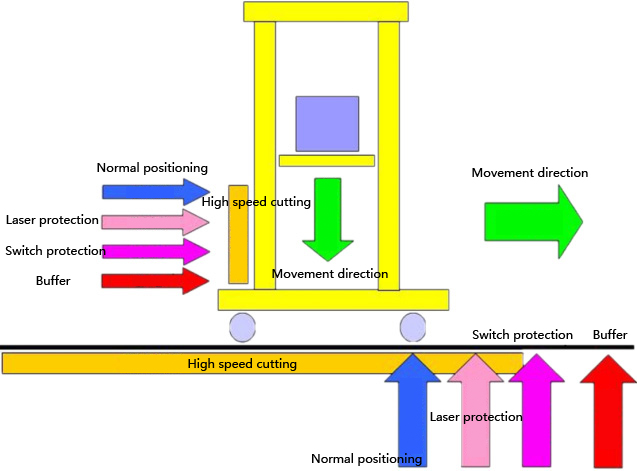

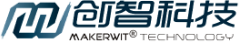

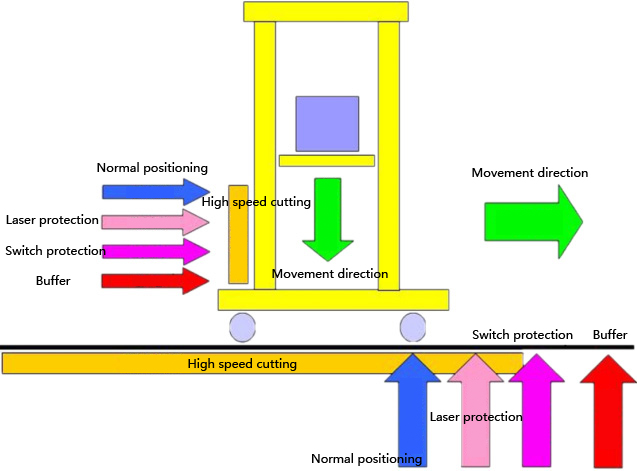

Direct mode: There is a stacker crane in each tunnel, and multiple stackers work simultaneously, cooperating with the warehouse delivery system to form a smooth logistics system. Scope of application: Logistics systems with high frequency of material inbound and outbound.

| Switch rail mode: Multiple tunnels share a stacker crane for inbound and outbound operations. The stacker crane can automatically switch between each aisle through a transfer car. Scope of application: Logistics systems with low frequency of inbound and outbound operations. | Turning mode: Two lanes share a stacker crane for inbound and outbound operations. Switch between two tunnels using a turning stacker crane. Scope of application: Logistics systems with low frequency of inbound and outbound operations. |

Safety performance of stacker cranes

1. Loose or broken steel wire rope (or chain) protection device: When the steel wire rope (or chain) is loose or broken, the cargo platform overspeed drops, and the stacker crane overspeed protection device emergency brakes, which can timely clamp to prevent the cargo platform from falling, and at the same time issue an alarm.

2. Overload protection device: When the three-way running motor of the stacker crane is overloaded, the stacker crane will emergency brake and issue an alarm at the same time.

3. Forced deceleration protection device: Ensure that when the stacker crane runs horizontally beyond the cargo positions at both ends of the shelf and moves towards the outside of the shelf, it is forced to switch to low speed to prevent the stacker crane from colliding with the end of the aisle at high speed;

4. Fork mid position protection device: The stacker's onboard cargo platform is equipped with a mid position double safety limit switch to prevent the stacker from moving or lifting incorrectly without the fork returning to the center, ensuring the safety of the stacker's operation;

5. Storage space virtual and physical inspection device: Before the stacker crane unloads the goods into the storage space, the photoelectric device will be used to check whether there is cargo in the shelf storage space to prevent repeated unloading;

6. Using infrared detection sensors to dynamically detect whether the cargo size is qualified;

7. Communication anomaly detection;

8. Emergency stop protection device: can be used in the event of mechanical or electrical failure, and will automatically protect the system from being in a stopped state.